2019-11-06

The largest in the world of its kind

Manufacturer RINGSPANN is once again setting standards in the field of freewheel technology

A few days ago, RINGSPANN completed the world’s largest housing freewheel in technological history for an Asian client. It is the latest member of the FH series and is used in the energy recovery system of a petrochemical plant. As a wear-free overrunning clutch it generates a maximum nominal torque of 81,850 Nm at 1,400 rpm. With this innovative new development, RINGSPANN is entering completely new dimensions in freewheel technology and is once again setting international standards.

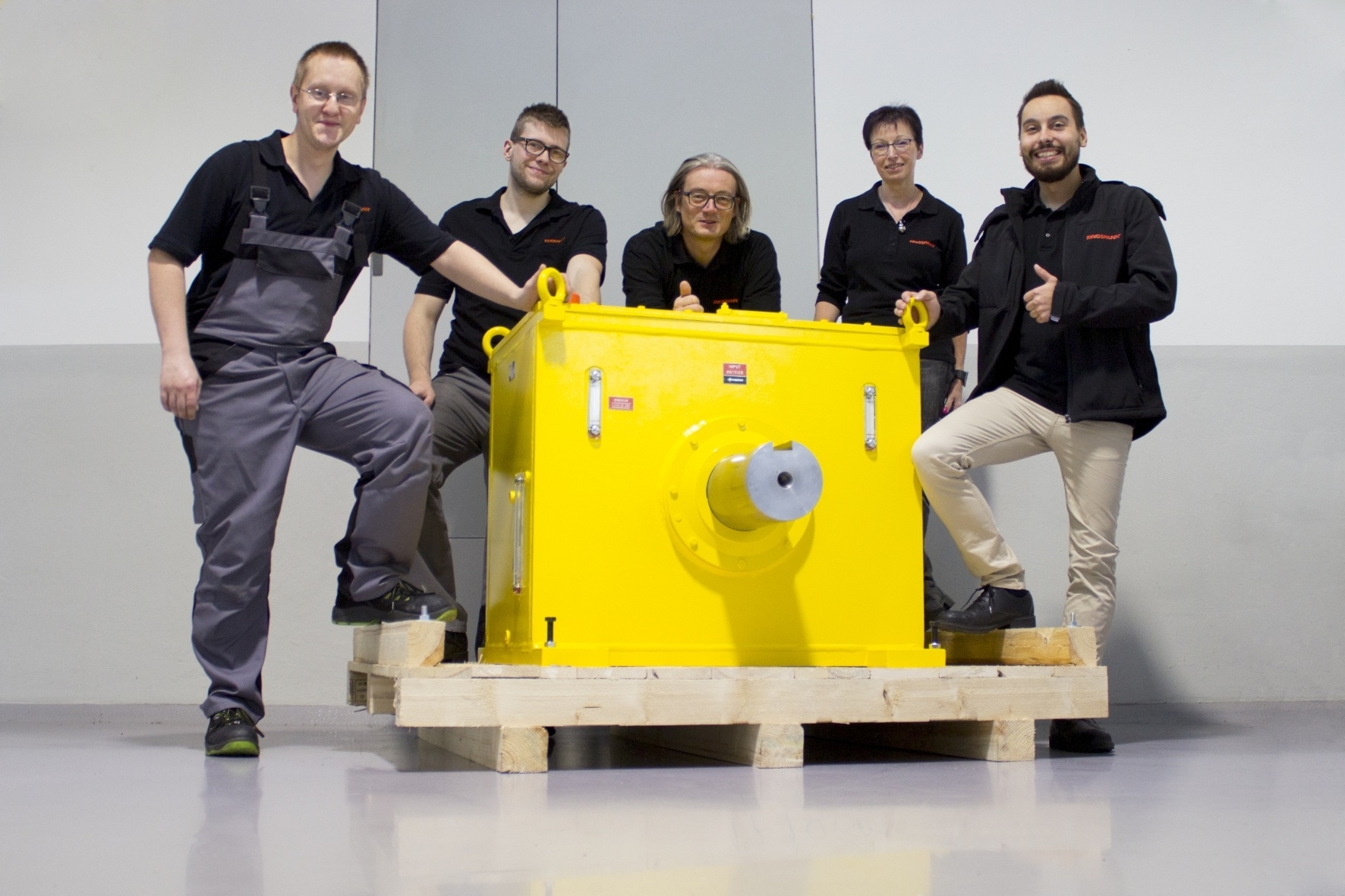

Bad Homburg, October 2019. – With the realisation of the largest and most powerful housing freewheel to date in the FH 60,000 R, RINGSPANN once again underlines its leading position as an innovative manufacturer in the field of freewheel technology. Completed just a few days ago, the first two of these 1.7-tonne-heavy units are currently ready for shipment to Asia. Instead of expensive and complex clutches, they will be used as speed-dependent, wear-free overrunning clutches in the drive trains of the energy recovery system of a large petrochemical plant. They are designed for revolutions of up to 1,400 rpm and provide a maximum nominal torque of 81,850 Nm. Their external dimensions are 1,260 x 970 x 890 mm.

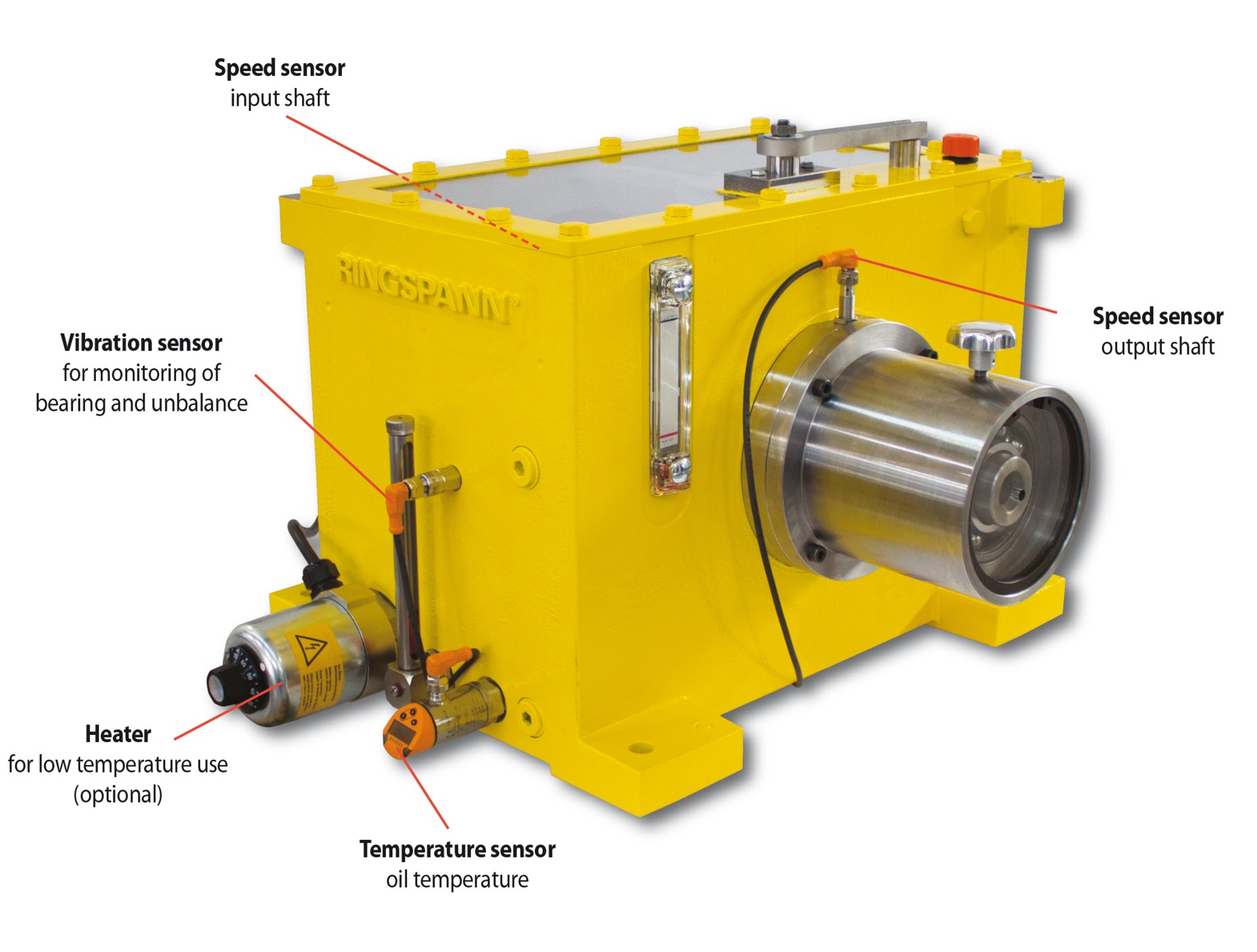

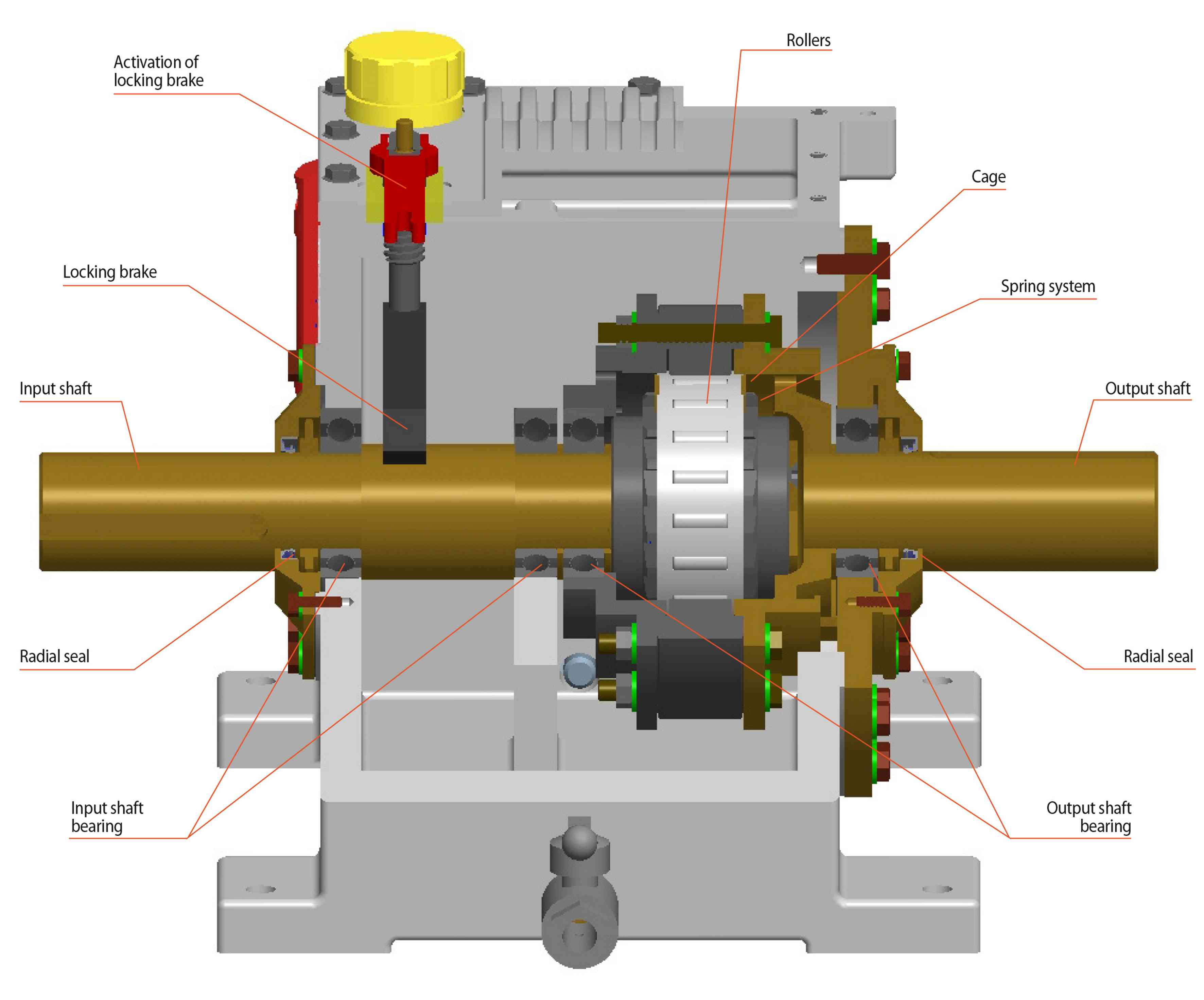

Like all overrunning clutches in the FH series, the new FH 60,000 R is characterised by a very high degree of reliability, low-noise operation and minimal maintenance. Designed as an encapsulated unit with an integrated oil filter system and built-in locking brake, it requires no external oil supply. Thomas Heubach, head of the freewheels division at RINGSPANN, further stresses: “The new FH 60,000 Rs are also designed for maximum continuous service life and work wear-free thanks to their hydrodynamic clamping roller lift-off. In terms of the normal maintenance, the operator only needs to plan for the regular oil change. It is precisely because of the hydrodynamic clamping roller lift-off that the RINGSPANN FH series housing freewheels are viewed as a high-performance overrunning clutch solution for stationary applications in which a unit is to be driven by several motors or turbines at the same speed or a similar speed. If one drive source should fail, they allow the system to continue running without a hitch. They are also suitable for switching a drive system to partial load operation – for example with the aim of saving energy.

Complete solution from a single source

RINGSPANN’s freewheels division needed no more than 16 weeks to develop and produce the new FH 60,000 R. “To achieve such fast implementation times, we have an efficient process management system in which the various departments of purchasing, design, production, quality assurance and logistics work together like clockwork,” says Thomas Heubach. The innovative modular concept of RINGSPANN’s FH series also made a key contribution to the rapid completion of the new housing freewheel. And as usual in the case of customer-specific special solutions with small batch sizes, the exceptionally large and thick-walled housing of the FH 60,000 R was designed as a welded construction. This once again yielded a considerable time advantage over the cast version. RINGSPANN had the housing certified with regards to welding technology, tightness and connection dimensions to cover all approval requirements and provide the customer with a ready-to-install solution.

Next frame size in planning

With the FH 60,000 R, RINGSPANN offers a completely new freewheel size, which opens up previously unimaginable possibilities, especially for international plant manufacturers in the petrochemical, energy technology and coal and steel industries. And yet if you think this new housing freewheel marks the end of the RINGSPANN innovation spiral, think again. “We are already planning the next frame size. It follows the design principles of all FH freewheels, but will achieve enormous nominal torques of up to 122,000 Nm at speeds of 1,200 rpm”, announces division manager Thomas Heubach.

By the way: all housing freewheels from the FH series can also be equipped with a heater and the sensor and telematics tools of RINGSPANN’s new Condition Monitoring System on request. This CMS system enables operators of complex multi-motor systems and their maintenance staff to monitor all the key power and MRO parameters of the installed freewheels in real time. This complete solution includes data analysis, remote maintenance and functional integration into higher-level control systems.