2019-08-02

More play in gearing

The expanding sleeve mandrel HDDS is becoming the standard for mechanical engineers

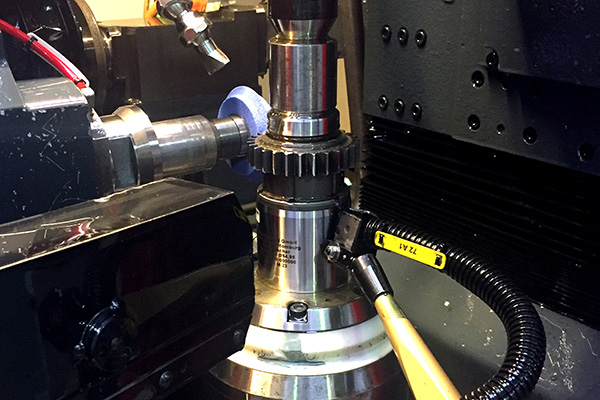

Manufacturers of gear cutting machines and users in the field of fine machining should make a beeline for Booth E22 in Hall 3 at this year’s EMO. Here, RINGSPANN will once again be presenting the youngest star of its comprehensive clamping fixture range: The mechanical expanding sleeve mandrel HDDS. As a both precise and flexible alternative to hydraulic expanding clamping tools, it has since provided multiple examples of its performance capability in various gear wheel assemblies. It is currently under discussion by the first manufacturers to become part of the standard configuration of their gear cutting machines.

Bad Homburg, August 2019. – Increasing demands on accuracy have for years determined the mechanical production of spur or taper wheels for gear manufacturing. While gearing qualities of 8 or 9 in accordance with DIN 3961 used to be viewed as sufficient for most applications in this area of fine machining, today clients often write qualities of 7 or 6 into the product specification of their suppliers. Even higher are the demands on gear wheels for motorsports – here, gearing qualities of 5 or 4 have long since become standard. “The clamping tools deployed during machining – in addition to the machines and tools – play a key role in achieving such qualities. Ideally, they support gearing technicians not only when fulfilling increasing quality demands, but also offer them more manufacturing flexibility and economic leeway”, says RINGSPANN’s Volker Schlautmann. Visitors of this year’s EMO will get a glimpse of how the concrete proposal of the head of sales and design of the company division clamping fixtures looks in Hall 3 at Booth E22. Because that is where RINGSPANN will once again be showcasing the latest star of its current clamping fixtures range: The mechanical expanding sleeve mandrel HDDS.

More flexibility thanks to greater expansion

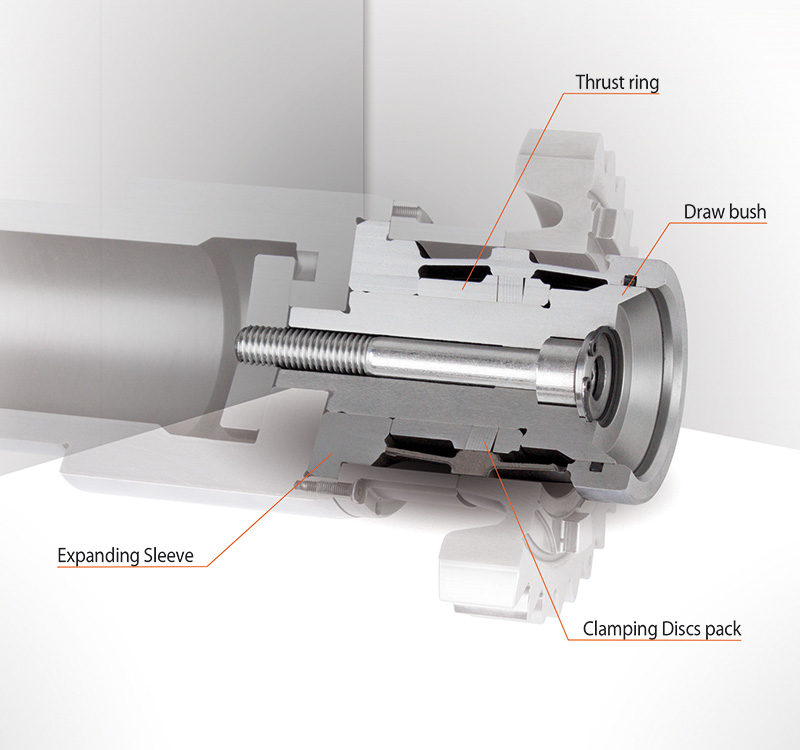

The HDDS by RINGSPANN is an innovative inner clamping system and the mechanical alternative to the hydraulic expanding clamping mandrels which are widespread in gearing technology. It stands out thanks to its true running accuracy of ≤ 5 µm and achieves an absolute expansion that is four times larger than most hydraulic clamping fixtures. Volker Schlautmann tells us what this means for the user: “Our HDDS can take up workpieces with bores of up to tolerance class IT10. Most hydraulic clamping fixtures, meanwhile, are only suited to take up workpiece bores up to tolerance class IT7.”

Unlike hydraulic expanding clamping mandrels, RINGSPANN’s purely mechanical expanding sleeve mandrel offers an additional key advantage: Its use is completely free of leakage risks. This provides more process safety in series production, since even the smallest leakages of hydraulic clamping fixtures lead to process interruptions, malfunctions and increased repair outlay. The only source of wear for RINGSPANN’s HDDS are its clamping discs. These are, however, quality products from our own production that furthermore can be replaced by the user. The clamping mandrel doesn’t need to be taken from the spindle to do so.

Advantages for users and mechanical engineers

Since its premiere at the end of 2016, the HDDS by RINGSPANN has already proven itself in numerous demanding applications in gearing technology. Among other things, it has been able to prove its performance capability in the production of a Swiss gear manufacturer in the high-precision grinding of spur wheels – metrologically documented! Volker Schlautmann reports: “The axial run-out and true running accuracy of our expanding sleeve mandrel was tested both using a control workpiece with a tactile measuring device accurate to the micrometre as well as on an original blank with a coordinate measuring system. In the test run, the measuring device showed ≤ 2 µm for the axial run-out and ≤ 3 µm for the true running, and with the series workpiece the achieved geometry accuracy of the involute gearing was significantly below the defined tolerance limits – the HDDS thus significantly exceeded the expectations of the customer.”

The expanding sleeve mandrel from RINGSPANN is now under discussion with Swiss and US manufacturers of gearing machines as a component of the factory standard configuration of their machines. The reason for this: It enables not only the realisation of high gearing qualities, but further facilitates the simple implementation of fully automated manufacturing concepts. Clamping fixtures specialist Schlautmann explains: “For physical reasons, hydraulic expanding clamping mandrels exhibit a rather low expansion rate, which is why the handling systems used for their feeding demand a high degree of kinematic precision, which in turn requires rather high levels of investment in measurement and control technology of the periphery. This outlay is significantly reduced with the use of our HDDS, since it shows itself to be much more tolerant due to its high expansion rate.” The machines can be designed more simply and this paves the way for the user to gain a significantly more cost-efficient entry into fully automated processing.

Small diameters, short clamping lengths

Furthermore, the gearing technicians will discover at RINGSPANN’s EMO booth in Hall 3 that the HDDS – depending on the version – can clamp bores from diameters of 23 mm and that it is even suitable for bores whose inner geometry is interrupted by a groove. An additional benefit: It is also a solution for the processing of workpieces with very short clamping lengths, because its mechanics perform a pull-back action, where the workpiece is pressed against a backstop and aligned.

The HDDS at the VDMA Technologieforum at the EMO

As a particularly innovative solution in clamping technology, the mechanical expanding sleeve mandrel HDDS of RINGSPANN forms a thematic focus at the VDMA Technologieforum at the EMO in Hall 4 at Booth D39. Divisional manager Volker Schlautmann will present the operating principle and benefits here on 17.9.19 at 11:30 a.m. in a concentrated short lecture (in German language).